Description

Revolutionize Your Agricultural Operations with Our High-Capacity Pulse Processing Plant

Maximize Efficiency and Profitability with Our State-of-the-Art Solution

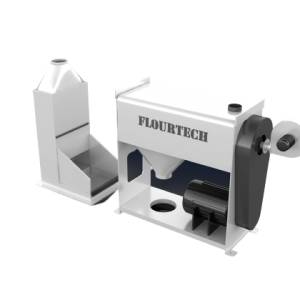

Our comprehensive Pulse Processing Plant offers a complete solution for the efficient and profitable processing of pulses, including lentils, chickpeas, beans, and peas. Designed for scalability and adaptability, this plant is ideal for both small-scale farmers and large-scale agricultural businesses seeking to optimize their operations and enhance product quality.

Key Features and Benefits:

- High Throughput Capacity: Process significant volumes of pulses in minimal time, significantly increasing your output and meeting market demands efficiently. Specific throughput capacity can be customized based on your individual needs and projected volume.

- Modular Design for Flexibility: The plant's modular construction allows for easy customization and scalability. Add or remove modules as your business grows, ensuring long-term investment value and adaptable capacity.

- Advanced Cleaning & Sorting: Employing advanced technologies like sieves, aspiration systems, and optical sorters, the plant ensures the removal of impurities, foreign materials, and damaged pulses, resulting in superior product quality and enhanced market value.

- Efficient De-hulling & Splitting: Precision de-hulling and splitting mechanisms ensure minimal breakage and maximized yield, preserving the nutritional integrity and market appeal of your processed pulses. Customized configurations cater to different pulse types and desired end-products.

- Automated Grading & Sizing: Automated grading and sizing systems categorize pulses according to size and quality, facilitating efficient packaging and meeting specific customer requirements. This ensures consistent product quality and minimizes manual labor.

- Hygienic & Safe Operation: Built with food-grade materials and designed to meet stringent hygiene standards, the plant minimizes the risk of contamination and ensures the safety of your final product. Our design adheres to all relevant industry regulations and certifications.

- Minimal Waste & Maximum Yield: Our optimized processing techniques minimize waste and maximize the yield of valuable pulse products, resulting in improved profitability and reduced environmental impact.

- User-Friendly Control System: Intuitive control systems allow for easy operation and monitoring of the entire processing line. Comprehensive data logging and reporting features provide valuable insights for process optimization and quality control.

Customization Options:

We offer a range of customization options to tailor the plant to your specific needs, including:

- Capacity: Select a plant capacity that aligns with your current and future processing needs.

- Pulse Type: Configure the plant to optimally handle your specific types of pulses.

- Processing Steps: Customize the processing stages to achieve your desired end-product specifications (e.g., whole, split, de-hulled).

- Automation Level: Choose the level of automation that best fits your operational requirements and budget.

Our Commitment:

We are committed to providing exceptional customer support, including comprehensive training, installation assistance, and ongoing maintenance services. Our team of experienced engineers and technicians ensures the smooth and efficient operation of your Pulse Processing Plant.

Contact us today to discuss your specific requirements and receive a customized quote. Let us help you unlock the full potential of your pulse processing operations.