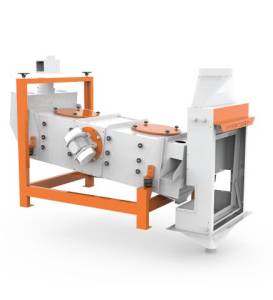

Revolutionize your material processing with our robust and reliable Vibro Classifier. This advanced piece of equipment offers precise and efficient separation of granular materials based on particle size, ensuring consistent product quality and maximizing your throughput. Ideal for a wide range of industries, our Vibro Classifier delivers superior performance and long-term operational reliability.

Key Features & Benefits:

Technical Specifications: (Specific details will vary depending on model. Contact us for detailed specifications for your application)

Contact us today to discuss your specific material processing needs and let our experts help you select the optimal Vibro Classifier for your application. We offer comprehensive solutions including installation, training, and ongoing technical support. Improve your efficiency and profitability – choose our Vibro Classifier.