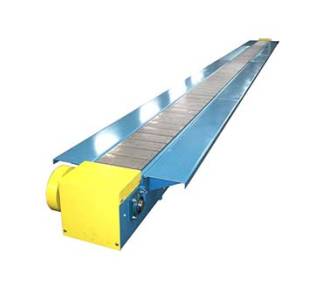

Screw conveyors, also known as auger conveyors or spiral conveyors, are highly versatile and efficient machines used for the conveying of a wide range of bulk materials. They are ideal for moving materials horizontally, inclined, or even vertically, making them suitable for a vast array of industries and applications. Our screw conveyors offer superior performance, durability, and cost-effectiveness.

Key Features and Benefits:

Applications:

Screw conveyors find applications in a wide range of industries, including:

Specifications:

(Note: Specific specifications will vary depending on the customized design. Please contact us for a detailed quotation based on your requirements.)

Contact Us:

For more information about our screw conveyors, including custom design options and pricing, please contact us today. We are happy to discuss your specific requirements and provide you with a tailored solution. Let us help you optimize your material handling processes.