Description

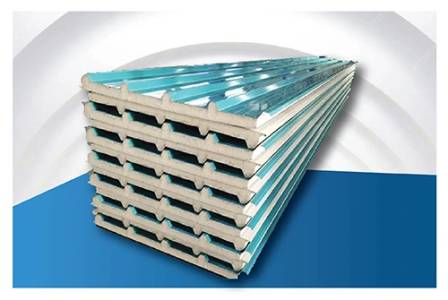

Superior Thermal & Structural Performance: Roof PUF Panels

Revolutionize your roofing solutions with our advanced Roof PUF Panels. Engineered for unparalleled thermal insulation, structural integrity, and rapid installation, our Polyurethane Foam (PUF) sandwich panels are the smart choice for modern construction. Designed to deliver long-term energy savings and a comfortable indoor environment, these panels are ideal for a wide range of industrial, commercial, and agricultural applications.

Why Choose Our Roof PUF Panels?

Our Roof PUF Panels combine cutting-edge insulation technology with durable, high-strength materials to create a roofing system that outperforms traditional methods. Experience the perfect blend of efficiency, aesthetics, and longevity.

Key Features & Benefits:

- Unrivaled Thermal Insulation:

- High R-Value: At the core of each panel is high-density Polyurethane Foam, known for its exceptionally low thermal conductivity (λ-value). This translates to superior insulation properties, significantly reducing heat transfer.

- Energy Efficiency: Drastically lowers heating and cooling costs by maintaining a consistent internal temperature, leading to substantial savings on utility bills.

- Enhanced Comfort: Creates a more stable and comfortable indoor environment, reducing the reliance on HVAC systems.

- Exceptional Structural Strength & Durability:

- Sandwich Panel Design: Comprised of a rigid PUF core bonded between two high-strength, pre-painted metal skins (typically PPGI - Pre-Painted Galvanized Iron or Galvalume). This creates a lightweight yet robust composite structure.

- Load-Bearing Capability: Capable of spanning long distances without the need for extensive secondary support structures, simplifying design and reducing material costs.

- Weather Resistant Skins: The metal skins are treated with specialized coatings (e.g., polyester, PVDF) providing excellent resistance against corrosion, UV radiation, extreme weather conditions, and general wear and tear, ensuring a long service life.

- Lightweight & Rapid Installation:

- Modular & Pre-Fabricated: Panels are manufactured to precise specifications, arriving ready for installation.

- Tongue & Groove System: Designed with an interlocking joint system for quick, secure, and weather-tight assembly, significantly reducing installation time and labor costs.

- Reduced Construction Time: Speeds up project completion, allowing for earlier occupancy and operational readiness.

- Superior Weatherproofing & Leak Prevention:

- Integrated Sealing: The interlocking design and potential for integrated sealing tapes create a continuous, impermeable roof membrane, virtually eliminating the risk of leaks.

- High Performance: Provides robust protection against rain, wind, hail, and snow, ensuring the integrity of your building's interior.

- Aesthetic Versatility:

- Variety of Colors & Profiles: Available in a wide range of standard and custom colors, and various profiles (e.g., ribbed, flat, tiled effect) to complement any architectural design and enhance the building's curb appeal.

- Clean Finish: Offers a modern, clean, and attractive finish for both the exterior and interior of the roof.

- Fire Safety (Optional):

- Available with fire-retardant additives in the PUF core, meeting specific fire rating requirements and enhancing building safety.

- Eco-Friendly Design:

- Manufactured using CFC and HCFC-free blowing agents, contributing to environmental protection and compliance with green building standards.

Technical Specifications:

- Core Material: High-Density Polyurethane Foam (PUF)

- Core Density: 38-42 kg/m³ (standard, other densities available)

- Skin Material:

- Pre-Painted Galvanized Iron (PPGI)

- Pre-Painted Galvalume Steel

- Aluminum (on request)

- Skin Thickness: 0.40 mm to 0.80 mm (standard, other gauges available)

- Panel Thickness (Overall): 30 mm, 40 mm, 50 mm, 75 mm, 100 mm, 125 mm, 150 mm (and up)

- Panel Width (Effective Cover): Typically 1000 mm (other widths available)

- Panel Length: Customizable, up to 12 meters (or more depending on logistics)

- Thermal Conductivity (λ-value): ≤ 0.023 W/mK (at 20°C)

- Fire Rating: Depending on specifications, may achieve B or C Class fire ratings (as per specific standards like ASTM, EN, or local codes).

- Coatings: SP (Standard Polyester), SMP (Silicon Modified Polyester), PVDF (Polyvinylidene Fluoride)

Ideal Applications:

- Industrial Buildings: Factories, manufacturing units, workshops

- Warehouses & Logistics Centers: Storage facilities, distribution hubs

- Commercial Structures: Shopping malls, showrooms, office complexes

- Cold Storage: Refrigerated warehouses, food processing units

- Agricultural Buildings: Barns, poultry farms, dairy sheds

- Clean Rooms: Pharmaceutical, electronics, and food industries

- Portable Cabins & Modular Construction

- Sports Facilities & Auditoriums

Invest in the Future of Roofing

Our Roof PUF Panels represent a smart investment for any construction project. Experience superior thermal performance, robust structural integrity, and accelerated project timelines, all while reducing your operational costs and environmental footprint.

Ready to upgrade your roofing with a solution that delivers superior performance and value?

Contact us today for a free consultation and quote! Let our experts help you choose the perfect Roof PUF Panels for your project.

📞 [Your Phone Number] 📧 [Your Email Address] 🌐 [Your Website] 📍 [Your Company Address]