Seam welding is a resistance welding process that creates a continuous, leak-proof weld along the edges of overlapping sheet metal. Ideal for high-volume production, it offers unmatched speed and efficiency for joining similar metals, resulting in strong, durable, and aesthetically pleasing welds. This robust technique is crucial across numerous industries, from automotive manufacturing and appliance production to the creation of HVAC systems and packaging.

Seam welding finds applications across a diverse range of industries and products:

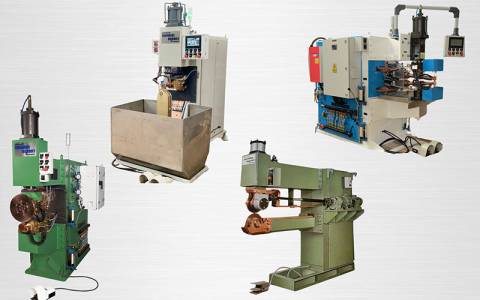

Several variations exist to adapt to different needs:

Selecting the ideal seam welding system depends on various factors, including:

Contact us today to discuss your specific requirements and find the perfect seam welding solution for your production needs.