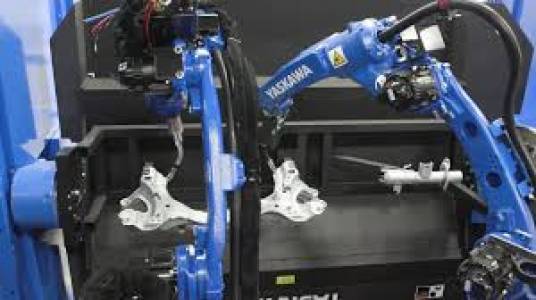

Tired of inconsistent weld quality, labor shortages, and high production costs? Our advanced welding automation systems offer a complete solution, streamlining your welding operations and delivering superior results. Whether you're a large manufacturer or a smaller fabrication shop, our customizable systems adapt to your specific needs and budget.

Key Benefits:

Our Automation Expertise Includes:

Why Choose Us?

Ready to transform your welding process? Contact us today for a free consultation and let us help you achieve greater efficiency, productivity, and profitability.

[Contact Information Here]