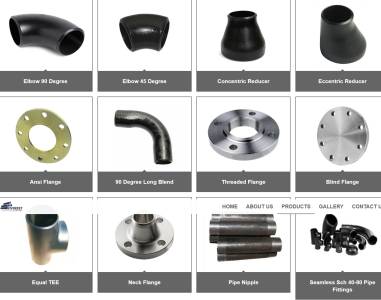

High-quality MS (Mild Steel) and GI (Galvanized Iron) buttweld fittings provide a robust and reliable solution for a wide range of piping applications. These fittings are known for their superior strength, durability, and leak-proof connections, making them ideal for high-pressure and demanding environments. Our extensive range caters to diverse industrial needs, ensuring you find the perfect fit for your project.

Key Features & Benefits:

Materials:

Applications:

Standards & Certifications:

Our MS & GI buttweld fittings are manufactured to comply with relevant international and national standards (Specify relevant standards here, e.g., ASME B16.9, EN 10253). We can also provide certifications upon request.

Ordering Information:

To place an order or request a quote, please provide the following information:

Contact us today to discuss your specific requirements and let our experts help you select the right MS & GI buttweld fittings for your project. We are committed to providing high-quality products and exceptional customer service.