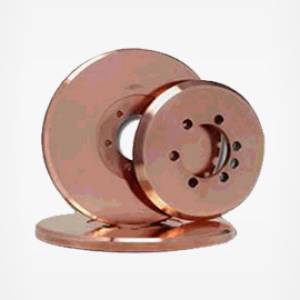

Description

Chromium Zirconium Copper Alloys: Superior Performance in Demanding Environments

Chromium zirconium copper alloys offer a unique combination of properties making them ideal for applications requiring high strength, excellent corrosion resistance, and enhanced electrical conductivity. These alloys are a specialized class of copper alloys, distinguished by the addition of chromium and zirconium, which significantly improve their overall performance compared to standard copper alloys.

Key Properties & Benefits:

- Exceptional Corrosion Resistance: The addition of chromium forms a passive chromium oxide layer on the surface, providing outstanding resistance to oxidation, tarnish, and corrosion in various environments, including seawater, industrial atmospheres, and aggressive chemicals. Zirconium further enhances this resistance, contributing to long-term durability and reduced maintenance.

- High Strength and Hardness: Compared to standard copper, these alloys exhibit significantly higher tensile strength and hardness, allowing for the design of thinner, lighter components without sacrificing structural integrity. This is particularly advantageous in applications where weight reduction is crucial.

- Excellent Electrical Conductivity: While not as high as pure copper, chromium zirconium copper alloys retain good electrical conductivity, making them suitable for applications where both electrical performance and corrosion resistance are critical. This balance makes them ideal for specialized electrical connectors and components.

- Enhanced Thermal Conductivity: These alloys also demonstrate improved thermal conductivity compared to many high-strength copper alloys, making them suitable for heat transfer applications.

- Improved Weldability and Formability: While some high-strength alloys can be challenging to process, these alloys offer good weldability and formability, allowing for efficient manufacturing techniques.

Typical Applications:

- Marine Environments: Components exposed to seawater, such as heat exchangers, piping, and fittings.

- Chemical Processing: Equipment and components used in chemical plants handling corrosive fluids.

- Electrical Connectors and Components: High-performance connectors, busbars, and other electrical components requiring both conductivity and corrosion resistance.

- Heat Exchangers: Applications requiring efficient heat transfer in corrosive environments.

- High-Stress Components: Parts subjected to significant mechanical stress, where both strength and corrosion resistance are vital.

Alloy Compositions & Variations:

The specific composition of chromium zirconium copper alloys can be tailored to meet the requirements of different applications. The precise percentages of chromium and zirconium, as well as other potential alloying elements, will influence the final properties of the material. Consult our technical data sheets for detailed information on available alloys and their corresponding properties.

Why Choose Chromium Zirconium Copper Alloys?

Choosing a chromium zirconium copper alloy represents a strategic decision to maximize performance and longevity in demanding applications. Their unique blend of properties translates to reduced maintenance, extended service life, and improved overall system reliability.

Contact Us:

For more information on specific alloy grades, availability, and pricing, please contact our sales team. We are happy to assist you in selecting the optimal alloy for your application.