Description

Here's a detailed product description for Aluminium Busbars, formatted in Markdown:

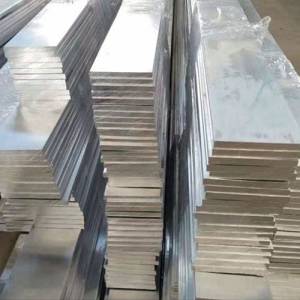

Premium Aluminium Busbars: Efficient & Economical Power Distribution

Optimize Your Electrical Systems with Lightweight, High-Performance Aluminium

Our Aluminium Busbars are a critical component for robust and efficient electrical power distribution in a wide range of applications. Engineered from high-grade electrical aluminium alloys, these busbars offer a compelling combination of lightweight design, excellent conductivity, and significant cost savings compared to traditional copper solutions, without compromising performance or reliability.

Designed for durability and precision, our aluminium busbars provide a stable and secure pathway for high currents, ensuring maximum power transfer and minimal energy loss.

Key Features

- High-Grade Electrical Aluminium: Manufactured from premium alloys such as AA1050, AA1350, or similar, specifically chosen for their superior electrical conductivity and mechanical properties.

- Excellent Conductivity: Offers a conductivity of typically 60-63% IACS (International Annealed Copper Standard), providing efficient power transmission.

- Lightweight Advantage: Significantly lighter than copper, facilitating easier handling, reducing structural load on installations, and lowering shipping costs.

- Cost-Effective Solution: Provides a more economical alternative to copper busbars, delivering substantial cost savings on materials, especially in large-scale projects.

- Optimal Thermal Performance: Aluminium effectively dissipates heat, contributing to stable operating temperatures and preventing overheating in high-current applications.

- Versatile Surface Finishes: Available in various finishes to suit specific environmental and connection requirements:

- Mill Finish (Bare): Standard, cost-effective.

- Tin Plated: Enhances corrosion resistance, improves contact interface, and reduces oxidation at connection points.

- Silver Plated: Offers superior conductivity and excellent corrosion resistance for critical high-performance applications.

- Nickel Plated: Provides good corrosion resistance and hardness, often used in specific chemical environments.

- High Mechanical Strength: Robust and durable, capable of withstanding the mechanical stresses of installation and operational vibrations.

- Customizable Profiles: Available in a wide range of standard and custom dimensions, including rectangular, square, and round profiles, to meet diverse design specifications.

- Ease of Fabrication: Aluminium is easily cut, punched, drilled, bent, and formed, allowing for straightforward customization and installation.

Benefits

- Reduced Overall Project Costs: Experience significant savings on material procurement and potentially on supporting structures due to lighter weight.

- Enhanced System Efficiency: Reliable conductivity minimizes voltage drop and power loss, leading to more efficient energy transfer.

- Extended Lifespan: With appropriate surface treatments and proper installation, our busbars resist corrosion and wear, ensuring long-term operational reliability.

- Simplified Installation: The lightweight nature of aluminium busbars makes them easier to transport, position, and install, reducing labor time and costs.

- Flexible Design Integration: Adaptable to various electrical panel configurations and equipment layouts due to a wide range of sizes and easy fabrication.

- Sustainable Choice: Aluminium is a highly recyclable material, contributing to more environmentally friendly electrical infrastructure projects.

Technical Specifications (Typical)

- Material: Electrical Grade Aluminium Alloy (e.g., AA1050, AA1350, EN AW-1050A, EN AW-1350)

- Purity: Typically ≥99.5% Aluminium

- Electrical Conductivity: 60-63% IACS @ 20°C

- Density: Approx. 2.7 g/cm³ (vs. ~8.96 g/cm³ for copper)

- Standard Profiles: Rectangular Bar, Square Bar, Round Bar

- Standard Dimensions:

- Thickness: 3mm to 30mm+ (e.g., 3mm, 5mm, 6mm, 10mm, 12mm, 15mm, 20mm)

- Width: 10mm to 200mm+ (e.g., 10mm, 20mm, 30mm, 40mm, 50mm, 80mm, 100mm, 120mm)

- Length: Up to 6 meters (custom lengths available)

- Surface Finishes: Mill Finish (Bare), Electroplated Tin, Electroplated Silver, Electroplated Nickel

- Hardness: Varies by alloy and temper (e.g., H111, H112)

- Tensile Strength: Varies by alloy and temper (e.g., 60-100 MPa)

- Standards Compliance: IEC 60060, ASTM B236, EN 1361, DIN, JIS (as applicable)

Typical Applications

Our Aluminium Busbars are ideally suited for a broad spectrum of power distribution needs, including:

- Switchgear & Control Panels: Internal wiring and connections.

- Transformer Connections: Efficient high-current links.

- Battery Banks & Energy Storage Systems: Critical for managing high DC currents.

- Solar PV & Wind Power Systems: Collecting and distributing renewable energy.

- Data Centers: Power distribution units (PDUs) and server racks.

- Industrial Power Distribution: Factories, manufacturing plants, heavy machinery.

- Grounding & Earthing Systems: Effective and economical grounding solutions.

- Electric Vehicle (EV) Charging Infrastructure: High-current connections for charging stations.

- Utilities & Substations: Medium to high voltage applications.

Why Choose Our Aluminium Busbars?

- Uncompromising Quality: We adhere to stringent quality control standards, utilizing only the finest electrical-grade aluminium to guarantee superior performance and longevity.

- Expertise & Reliability: Backed by extensive industry experience, our busbars are trusted by professionals for their consistent and dependable performance.

- Customization Capabilities: We offer comprehensive custom fabrication services, including specific dimensions, complex bending, punching, drilling, and specialized plating, to perfectly match your project requirements.

- Competitive Pricing: Benefit from the inherent cost advantages of aluminium, combined with our efficient manufacturing processes, to receive exceptional value.

- Dedicated Support: Our team of technical experts is available to provide guidance, answer your questions, and assist you in selecting the ideal busbar solution for your application.

Customization Options

Beyond standard offerings, we provide extensive customization to meet unique project demands:

- Precision Cutting & Shearing: To exact lengths.

- Punching & Drilling: For connection holes, mounting, and ventilation.

- Bending & Forming: Custom angles and shapes for complex installations.

- Insulation: Applied coatings or sleeving for enhanced safety and isolation.

- Special Alloys: Availability of specific aluminium alloys for unique requirements.

Ready to Optimize Your Power Distribution System?

Contact us today for a personalized quote and technical consultation. Let our experts help you design and implement the most efficient and cost-effective aluminium busbar solution for your next project.