Here's a detailed product description for a GI Angle, formatted in Markdown:

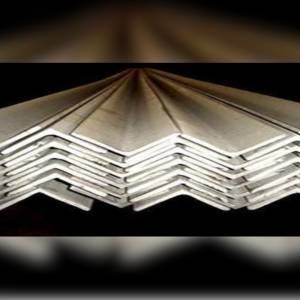

The GI Angle (Galvanized Iron Angle) is a robust and versatile structural component crafted from high-quality iron and protected by a durable zinc coating through the hot-dip galvanization process. Its distinctive L-shaped profile offers superior strength and rigidity, making it an indispensable material for a wide range of load-bearing, framing, and fabrication applications across various industries. Designed for exceptional longevity and performance, our GI Angle provides reliable support and excellent corrosion resistance, even in demanding environments.

Our GI Angles are widely used in sectors such as:

| Characteristic | Details |

|---|---|

| Material | Mild Steel (Carbon Steel) |

| Coating | Hot-Dip Galvanized (HDG) |

| Galvanization Standard | ASTM A123 (Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products) |

| Leg Size Range | 20mm x 20mm up to 150mm x 150mm (Equal and Unequal Leg options available) |

| Thickness Range | 3mm up to 12mm |

| Standard Lengths | 3 meters (10 ft), 6 meters (20 ft) - Custom lengths available upon request |

| Profile | L-shaped (90-degree angle) |

| Manufacturing Process | Hot Rolled followed by Hot-Dip Galvanization |

| Finish | Bright metallic, with potential for spangles (crystallization pattern of zinc) |

| Tolerance | Conforms to relevant industry standards for hot-rolled steel angles and galvanization. |

We offer a range of standard GI Angle sizes and can also accommodate custom requirements for specific projects. This includes:

For detailed specifications, custom quotes, or to place an order, please contact our sales team. We are committed to providing high-quality GI Angle solutions that meet your project's exact needs.