Description

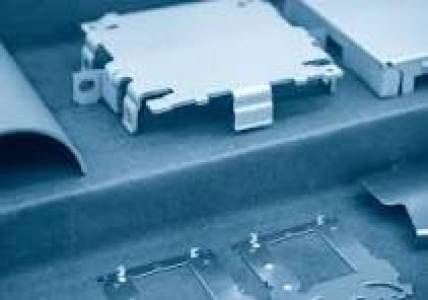

Precision Custom Sheet Metal Parts Fabrication Services

Unleash Your Vision with Expertly Crafted Sheet Metal Components

In a world where precision, durability, and cost-effectiveness are paramount, [Your Company Name] stands as your trusted partner for high-quality custom sheet metal parts. We transform raw metal sheets into intricate, robust, and aesthetically pleasing components that meet the exact specifications of your most demanding projects. From concept to production, our advanced capabilities and experienced team ensure every part delivers superior performance and value.

Why Choose Our Sheet Metal Parts?

Our commitment to excellence is reflected in every component we produce. When you partner with [Your Company Name], you benefit from:

- Unrivaled Precision: Utilizing state-of-the-art CNC machinery, we achieve tight tolerances and intricate geometries, ensuring your parts fit perfectly and function flawlessly.

- Extensive Material Selection: We work with a broad spectrum of metals, allowing you to select the ideal material for your application's strength, weight, corrosion resistance, and conductivity requirements.

- Comprehensive Fabrication Capabilities: From advanced laser cutting and punching to precise bending, welding, and finishing, we offer a full suite of services under one roof.

- Superior Quality Assurance: Our rigorous quality control processes, from material inspection to final dimension checks, guarantee that every part meets or exceeds industry standards and your expectations.

- Customization & Design Flexibility: Whether you have detailed CAD drawings or just a concept, our engineers can help optimize designs for manufacturability, cost, and performance.

- Cost-Effective Solutions: Our efficient processes, material optimization, and streamlined production minimize waste and overhead, providing competitive pricing without compromising quality.

- Rapid Prototyping & Production: We are equipped for quick turnaround on prototypes and efficient scaling for high-volume production runs, helping you meet tight deadlines.

- Expert Engineering Support: Our team offers valuable DFM (Design for Manufacturability) insights, helping you refine designs to enhance functionality, reduce costs, and accelerate time to market.

Our Capabilities & Manufacturing Processes

[Your Company Name] leverages cutting-edge technology and skilled craftsmanship to deliver exceptional sheet metal parts. Our core processes include:

1. Cutting & Perforating:

- CNC Laser Cutting: High-precision thermal cutting for complex shapes, fine details, and a wide range of material thicknesses with minimal heat distortion.

- CNC Plasma Cutting: Ideal for thicker metals, offering fast and cost-effective cutting for larger components.

- CNC Waterjet Cutting: Utilized for heat-sensitive materials and applications requiring extremely smooth edges without thermal distortion.

- CNC Punching: Rapid and efficient for creating holes, slots, and various patterns in sheet metal, especially for high-volume production.

2. Forming & Bending:

- CNC Press Brake Bending: Precisely forms angles, flanges, and complex bends in sheet metal with repeatable accuracy.

- Roll Forming: For creating long, consistent cross-sections and tubular shapes from flat sheet metal.

- Stamping & Deep Drawing: For mass production of parts requiring complex three-dimensional forms from a single piece of sheet metal.

3. Joining & Assembly:

- TIG & MIG Welding: High-strength, aesthetically pleasing welds for various material types and thicknesses.

- Spot Welding: Fast and efficient joining for overlapping sheet metal sections.

- Fastener Insertion: Integration of hardware such as studs, standoffs, and nuts for easy assembly.

4. Finishing Services:

- Powder Coating: Durable, attractive, and environmentally friendly finish available in a vast array of colors for enhanced corrosion resistance and aesthetics.

- Anodizing: (For Aluminum) Increases corrosion resistance, wear resistance, and provides a decorative finish.

- Plating (Zinc, Nickel, Chrome): Offers superior corrosion protection, hardness, and a decorative appearance.

- Polishing & Brushing: Improves surface finish and aesthetics.

- Deburring & Grinding: Removes sharp edges and imperfections for safety and improved part quality.

- Painting: Custom painting services to match specific color requirements.

- Screen Printing & Labeling: For branding, instructions, and identification.

Material Options

We fabricate custom parts from a diverse range of sheet metal materials, including but not limited to:

- Stainless Steel (304, 316, 430): Excellent corrosion resistance, strength, and hygienic properties, ideal for food, medical, and marine applications.

- Aluminum (3003, 5052, 6061): Lightweight, excellent strength-to-weight ratio, high conductivity, and corrosion resistance, perfect for aerospace, electronics, and automotive.

- Mild Steel / Carbon Steel (Cold Rolled, Hot Rolled): Cost-effective, strong, and highly weldable, suitable for structural components, machinery, and general fabrication.

- Galvanized Steel: Zinc-coated steel for enhanced corrosion protection, commonly used in outdoor and humid environments.

- Copper & Brass: High electrical and thermal conductivity, excellent formability, and decorative appeal for electrical components, architectural accents, and plumbing.

Typical Applications & Industries Served

Our custom sheet metal parts are integral to a multitude of industries and applications, including:

- Electronics Enclosures: Custom housings for servers, control panels, medical devices, and consumer electronics.

- Automotive Components: Brackets, chassis parts, decorative trim, and specialty vehicle parts.

- Medical Devices: Housings, sterilization trays, and internal components for diagnostic and treatment equipment.

- Aerospace & Defense: Brackets, structural components, and assemblies requiring high strength-to-weight ratios.

- HVAC Systems: Ducts, panels, and housings for heating, ventilation, and air conditioning units.

- Architectural Elements: Custom facades, decorative panels, railing components, and structural supports.

- Industrial Machinery: Guards, covers, frames, and functional components for manufacturing equipment.

- Consumer Goods: Appliance parts, furniture components, and specialized product housings.

The [Your Company Name] Advantage

At [Your Company Name], we combine cutting-edge technology with decades of collective experience. Our highly skilled technicians and engineers are dedicated to delivering not just parts, but solutions. We pride ourselves on:

- Advanced Technology: Investing in the latest fabrication equipment to ensure precision and efficiency.

- Skilled Workforce: A team of certified welders, experienced machine operators, and meticulous quality control specialists.

- Commitment to Quality: Adherence to strict quality management systems (e.g., ISO 9001 if applicable) to ensure consistent excellence.

- Customer-Centric Approach: We listen to your needs, provide clear communication, and work collaboratively to achieve your project goals.

Get Started Today!

Ready to bring your sheet metal designs to life with unparalleled precision and quality?

[Your Company Name] is here to make your project a success.

- Request a Free Quote: Upload your CAD files (DXF, DWG, STEP, SLDPRT) or detailed drawings for a fast and competitive quotation.

- Consult Our Experts: Contact our engineering team to discuss your project requirements, material selection, or design optimization.

[Call to Action: Link to Quote Request Form or Contact Page]

Contact Information:

- Phone: [Your Phone Number]

- Email: [Your Email Address]

- Website: [Your Website URL]

- Address: [Your Company Address]