Description

Here's a detailed product description for Brass Inserts, formatted in Markdown:

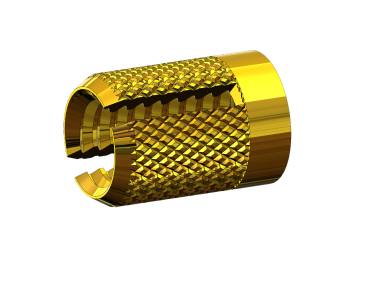

Robust Brass Inserts: Engineered for Superior Thread Strength in Plastics & Composites

Tired of stripped threads and unreliable fastening in your plastic, wood, or composite assemblies? Our premium Brass Inserts provide the ultimate solution for creating strong, durable, and reusable metal threads in softer materials. Designed for exceptional performance and ease of installation, these inserts significantly enhance the longevity and integrity of your products.

Why Choose Our Brass Inserts?

Our brass inserts are meticulously engineered to overcome the common challenges of fastening in plastics and other soft substrates. They transform weak, easily damaged threads into robust, long-lasting connection points.

Key Features & Benefits:

- Premium Brass Construction: Manufactured from high-grade brass (typically C36000 free-machining brass), offering excellent corrosion resistance, superior strength, and good thermal/electrical conductivity.

- Exceptional Thread Strength: Far outperforms direct tapping into plastic, providing significantly higher pull-out and torque-out resistance.

- Enhanced Durability: Designed to withstand repeated assembly and disassembly cycles without thread wear or degradation, ideal for maintenance access panels and modular designs.

- Versatile Compatibility: Perfectly suited for a wide range of materials including thermoplastics (ABS, PC, PP, PE, Nylon), thermosets, wood, particleboard, and composite materials.

- Efficient & Reliable Installation: Available in multiple designs optimized for various installation methods, ensuring fast, cost-effective, and secure integration into your parts.

- Optimized Design: Features specialized knurling patterns (straight, diagonal, undercut) and lead-ins to maximize grip and prevent rotation or displacement once installed.

- Flush & Professional Finish: Many designs allow for a flush surface finish, improving aesthetics and preventing snags.

Types & Installation Methods:

We offer a comprehensive range of brass inserts, each optimized for specific applications and installation techniques:

- 1. Heat-Set Inserts (Thermal Inserts):

- Description: The most common type, designed to be melted into a pre-drilled or molded hole using a heated tip. The brass transfers heat to the surrounding plastic, allowing the insert to be pressed in. As the plastic cools, it solidifies around the knurling, creating a very strong bond.

- Benefits: High pull-out and torque-out resistance, fast installation, ideal for high-volume production.

- Applications: Electronic enclosures, automotive interiors, medical devices.

- 2. Ultrasonic Inserts:

- Description: Similar to heat-set but installed using ultrasonic vibrations to generate localized heat, melting the plastic around the insert for a secure fit.

- Benefits: Extremely fast installation, precise control, minimal stress on the plastic.

- Applications: Sensitive electronic components, delicate plastic parts.

- 3. Press-Fit Inserts (Cold Pressed):

- Description: Designed to be simply pressed into a slightly undersized hole. External knurling bites into the material, creating an interference fit.

- Benefits: No heat required, simple installation, suitable for harder plastics and some wood applications.

- Applications: Lower stress applications, prototypes, repair work.

- 4. Self-Tapping Inserts:

- Description: Feature external cutting threads that tap their own thread into the base material as they are driven in.

- Benefits: No pre-tapped hole required, strong bond, suitable for tougher plastics and some metals.

- Applications: Repair kits, heavy-duty applications, materials that don't respond well to heat.

- 5. Molded-In Inserts:

- Description: Designed to be placed directly into an injection mold cavity before the plastic is injected, becoming an integral part of the finished component.

- Benefits: Highest possible pull-out and torque resistance, perfectly integrated, eliminates secondary operations.

- Applications: Critical structural components, high-stress assemblies, OEM parts.

Common Applications:

- Electronics: PCB mounting, enclosure assembly, sensor integration, battery compartments.

- Automotive: Interior trim, dashboards, lighting assemblies, control panels.

- Furniture & Fixtures: Knock-down assembly, shelving, handles, adjustable feet.

- Medical Devices: Housing assembly, diagnostic equipment, patient care devices.

- Consumer Goods: Appliances, toys, sporting equipment, power tools.

- Aerospace & Defense: Non-structural components, interior panels, instrumentation.

- Prototyping & Hobby Projects: Robust thread creation for custom enclosures and models.

Technical Specifications:

- Material: C36000 Free-Machining Brass (ASTM B16 / B455 equivalent)

- Thread Sizes: Metric (M2, M2.5, M3, M4, M5, M6, M8, M10) and Imperial (#2-56, #4-40, #6-32, #8-32, #10-32, 1/4"-20, 5/16"-18, 3/8"-16)

- Insert Lengths: Various standard lengths available to suit material thickness.

- External Design: Straight knurl, diagonal knurl, spiral knurl, barbed, self-tapping flutes.

- Lead-in: Tapered or pilot for easy insertion.

- Compliance: RoHS, REACH compliant materials available upon request.

Elevate Your Product's Design & Durability

Invest in the quality and reliability of our Brass Inserts. Enhance your product's performance, simplify assembly, and reduce manufacturing costs associated with stripped threads.

Browse our extensive catalog today to find the perfect brass insert solution for your specific application, or contact our technical team for custom requirements and expert guidance.