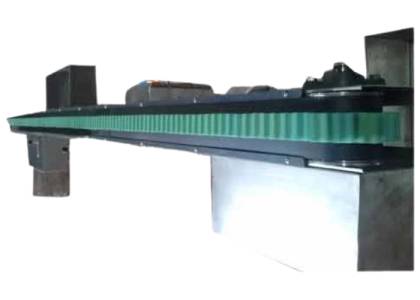

Our Cleated Conveyor Systems are specialized material handling solutions engineered to transport products securely and efficiently, particularly on inclines, declines, or when precise product spacing is required on horizontal runs. By utilizing strategically spaced cleats (or flights) integrated into the conveyor belt, these systems prevent product rollback, slippage, and accumulation, ensuring a controlled and gentle flow of materials. Ideal for a wide range of industries, our cleated conveyors are designed for durability, hygiene, and optimal performance in even the most demanding environments.

We understand that every application is unique. Our Cleated Conveyor Systems are highly customizable to meet your specific operational requirements:

With years of expertise in material handling, we deliver cleated conveyor solutions that are:

Elevate your production capabilities and achieve unparalleled control over your material flow.