Polymethylmethacrylate (PMMA), commonly known as acrylic glass or plexiglass, is a versatile thermoplastic polymer with exceptional optical clarity, impact resistance, and weatherability. This makes it a popular choice for a wide range of applications, from everyday consumer products to sophisticated engineering components.

Key Properties & Benefits:

Applications:

PMMA's versatile properties lend themselves to a multitude of applications, including:

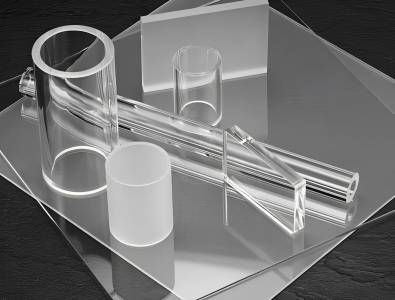

Available Forms:

PMMA is available in various forms, including:

Conclusion:

Polymethylmethacrylate (PMMA) is a high-performance polymer with a remarkable combination of optical clarity, impact resistance, and weatherability. Its versatility and ease of processing make it an excellent choice for a wide range of applications across various industries. Understanding its specific properties and limitations is key to selecting the appropriate grade for a given application.