Description

Here's a detailed product description for a Rail & Trolley Bucket system in Markdown format:

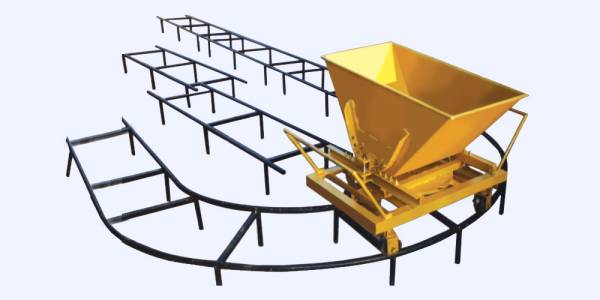

Streamline Material Handling with Our Robust Rail & Trolley Bucket System

Revolutionize Your Workflow with Unmatched Efficiency and Safety

Tired of inefficient, labor-intensive material transport? Introducing our Rail & Trolley Bucket System – the ultimate solution for moving bulk materials, waste, components, and liquids across various industrial and commercial environments. Designed for durability, versatility, and ease of use, this system significantly reduces manual labor, enhances safety, and boosts overall productivity.

Key Features:

Our Rail & Trolley Bucket system is engineered with precision and built to withstand the rigors of demanding applications:

- Heavy-Duty Construction:

- Bucket: Fabricated from high-grade steel (mild steel, galvanized, or stainless steel options available) for exceptional strength and longevity.

- Trolley: Robust steel frame with precision-engineered, smooth-gliding wheels for effortless movement along the rail.

- Rail System: Constructed from durable steel I-beams or enclosed track profiles, ensuring stability and a secure path.

- Versatile Bucket Options:

- Standard Tipping Buckets: Easily discharge materials with a manual or semi-automatic tipping mechanism.

- Bottom Discharge Buckets: For controlled, precise release of materials through a gate at the base.

- Fixed Buckets: Ideal for continuous transport of specific items or waste.

- Specialized Buckets: Available with features like watertight seals, perforated bases, or specific dimensions for unique requirements.

- Smooth & Reliable Trolley Movement:

- Low-Friction Wheels: Designed for quiet, efficient travel, reducing effort for manual systems.

- Anti-Derailment Design: Enhanced safety features to prevent the trolley from leaving the track.

- Optional Drive Systems: Manual push, chain-driven, or electric motor options for powered movement over longer distances or with heavier loads.

- Modular & Customizable Rail System:

- Flexible Layouts: Design custom routes, including straight sections, curves, inclines, and declines, to perfectly match your facility's layout.

- Overhead or Ground-Level Installation: Choose the configuration that best suits your space and operational needs, freeing up valuable floor space with overhead systems.

- Easy Installation: Modular components allow for straightforward assembly and potential future expansion.

- Enhanced Safety Features:

- Secure Locking Mechanisms: For buckets to prevent accidental discharge during transit.

- Controlled Movement: Minimizes the risk of spills, injuries, and damage to materials or infrastructure.

- Optional Brakes: For safe stopping and positioning on inclines or at workstations.

- Corrosion Resistance: Available finishes include powder coating, galvanization, or stainless steel construction for applications in harsh, humid, or corrosive environments.

Benefits You'll Experience:

Implementing our Rail & Trolley Bucket System brings a host of operational advantages:

- Increased Productivity: Rapid and efficient transport of materials reduces cycle times and keeps your operations flowing smoothly.

- Enhanced Safety: Eliminates the need for manual lifting and carrying, drastically reducing the risk of strain injuries, slips, and falls. Controlled movement prevents accidents and spills.

- Optimized Space Utilization: Overhead rail systems clear floor space, improving traffic flow and maximizing storage or workspace.

- Cost-Efficiency: Reduces labor costs associated with manual material handling and minimizes material waste due to efficient transport. Durable construction ensures a long operational life with minimal maintenance.

- Versatility: Adaptable to a wide range of materials and environments, from construction sites to cleanroom manufacturing.

- Improved Workflow: Creates a predictable and organized material flow, eliminating bottlenecks and improving overall operational synergy.

- Easy to Operate & Maintain: Simple design ensures user-friendly operation and straightforward maintenance, minimizing downtime.

Ideal Applications:

Our Rail & Trolley Bucket System is perfect for a diverse array of industries and tasks, including:

- Construction Sites: Moving debris, concrete, gravel, tools, and supplies.

- Manufacturing Plants: Transporting raw materials, work-in-progress components, and finished goods between workstations.

- Warehousing & Logistics: Order picking, moving items to packing stations, and waste removal.

- Food Processing: Hygienic transport of ingredients, by-products, or waste (with stainless steel options).

- Waste Management & Recycling: Collecting and transferring various types of waste materials.

- Foundries & Metalworking: Moving sand, scrap metal, and castings.

- Agriculture: Transporting feed, produce, or waste products.

- Chemical & Pharmaceutical: Controlled movement of sensitive materials (with specialized coatings/materials).

Technical Specifications (Customizable):

- Bucket Capacity: From 50 Liters (13 Gallons) up to 1000+ Liters (264+ Gallons), or equivalent weight capacity (e.g., 100 kg to 2000+ kg).

- Construction Material: Mild Steel, Galvanized Steel, Stainless Steel (304, 316).

- Rail Profile: I-Beam (e.g., S-beam, W-beam), Enclosed Track, Monorail.

- Trolley Drive: Manual Push, Hand Chain, Electric Motorized.

- Discharge Mechanism: Manual Tilt, Lever-Operated Bottom Gate, Automatic Release.

- Finish: Industrial Enamel Paint, Powder Coating, Hot-Dip Galvanized, Brushed/Polished Stainless Steel.

- Operating Environment: Indoor, Outdoor, High-Temperature, Corrosive (specify requirements).

Customization is Our Specialty:

We understand that every operation has unique demands. Our team of engineers can work with you to design a Rail & Trolley Bucket System that perfectly aligns with your specific material, capacity, layout, and environmental requirements. From custom bucket designs to automated track switching, we provide tailored solutions.

Invest in the future of your material handling. Choose our Rail & Trolley Bucket System for a safer, more efficient, and more productive operation.

Ready to Optimize Your Material Transport?

Contact us today for a free consultation and personalized quote! Let us help you design the perfect rail and trolley bucket solution for your business.