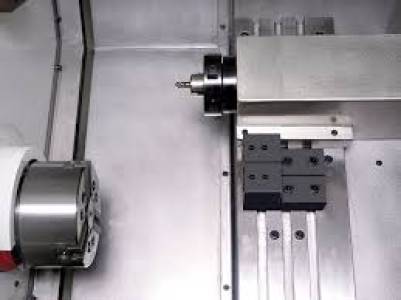

Elevate your CNC turning capabilities with our high-performance Flycut. Designed for demanding applications requiring exceptional surface finish and accuracy, this tool delivers unmatched efficiency and repeatability. Ideal for both small batch and high-volume production, our CNC Turning Flycut is engineered for longevity and optimized for minimal downtime.

Key Features & Benefits:

Specifications:

Applications:

Ordering Information:

Please contact us for detailed pricing and availability. Specify the required cutting diameter, shank diameter, overall length, insert type, and material when placing your order.

Warranty:

Our CNC Turning Flycut comes with a [Insert warranty period, e.g., one-year] warranty against manufacturing defects.

Contact Us:

For any questions or inquiries, please do not hesitate to contact our sales team at [Insert Contact Information].