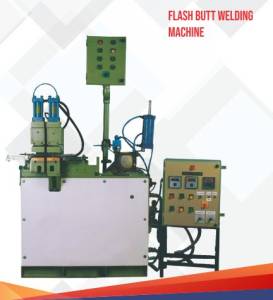

Our Flash Butt Welding Machine offers a robust and precise solution for joining metallic materials, delivering superior weld quality and significantly increased efficiency compared to traditional methods. Ideal for a wide range of industries, this machine is designed for both high-volume production and specialized applications requiring exceptional precision.

Key Features & Benefits:

Technical Specifications (Example - Specifics will vary based on model):

Applications:

Our Flash Butt Welding Machines find extensive use in various industries, including:

Contact us today to discuss your specific requirements and receive a customized quotation. We are committed to providing you with the optimal Flash Butt Welding solution for your needs.