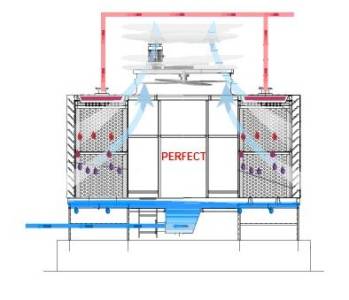

This robust and efficient Industrial Counter Flow Heat Exchanger is designed for demanding industrial applications requiring precise temperature control and optimal heat transfer. Engineered for longevity and high performance, it minimizes energy waste and maximizes operational efficiency across a wide range of industries.

Key Features & Benefits:

Technical Specifications: (This section needs to be filled with specific data based on the product offering)

Contact us today to discuss your specific requirements and receive a customized quotation. We'll work with you to select the ideal Industrial Counter Flow Heat Exchanger to meet your exact needs and budget.